Product Overview

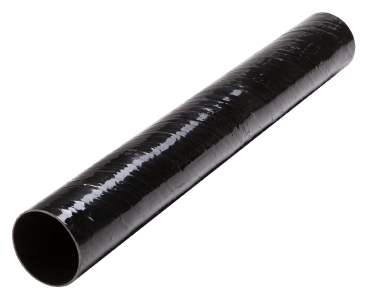

Champion Duct® (RTRC) electrical conduit offers dependability through quality design and unmatched versatility. Below ground, concrete encased, underbridge – and almost anywhere in between – Champion Duct delivers a range of benefits over other rigid electrical raceway conduit materials like PVC-coated steel and thin wall EMT conduit pipe, including ease of installation, fire and corrosion resistance, excellent impact resistance and more.

Champion Duct

Advantages

Champion Duct Conduit offers the following benefits:

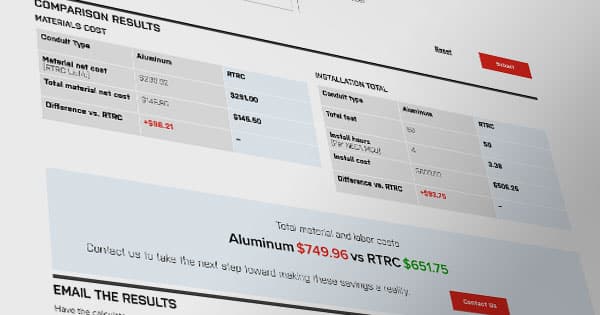

Lower installation costs

- The lowest man-hour installation rates for most diameters of electrical duct according to the National Electrical Contractors Association (NECA) Manual of Labor Units

- Lower total installation costs (labor plus material costs) for most diameters

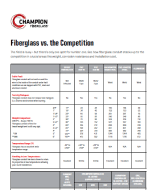

Enhanced performance over the other conduit systems

- Light weight contributes to installation ease, savings and safety

- Corrosion resistance to many chemicals

- No burn-through on elbows

- One of the lowest coefficients of friction of any in-market product

- Ability to retain its shape after impact or compression

- Withstands extreme conditions and temperatures

- Cable fault resistance —fiberglass duct will not melt or weld the wire to the inside of the conduit under fault conditions

- Extended UL Listed support spacing distances rival rigid steel conduit support spans.

Champion Duct

Engineering

Champion Duct Conduit meets the following specifications and requirements:

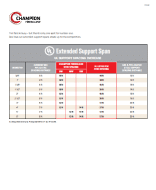

UL AND OTHER LISTINGS

- Standard Wall, Medium Wall (UL designates Champion Fiberglass MW for 5″ and 6″ as SW), and Heavy Wall conduits are UL Listed for newly expanded support spacing distances

- UL 2515 Listed for above and below ground installations

- UL 2420 Listed for below-ground installations

- CSA listed per CSA-22.2 No 211.3-96 standards

Fiberglass conduit is listed in Article 12-200 of the CEC (Canadian Electrical Code) as Rigid RTRC Conduit.

You’ll find it listed in the NEC (National Electrical Code) in Article 355 as Reinforced Thermosetting Resin Conduit.

A 100% DIGITAL FACILITY THAT STRIVES TO MEET ENVIRONMENTAL AND SYSTEM MANAGEMENT REQUIREMENTS

- ISO 9001 – Certified in quality management systems for over a decade

- ISO 14001 – World’s premier environmental management certification

- ISO 45001 – Certified occupational health and safety management systems

DATA SHEETS

SDS

CHAMPION DUCT

Catalog and Info

These resources will help you compare Champion Fiberglass Duct to other in-market conduit materials; the catalog is available for download or to review online.

FAQ

From ¾” to 12” and 11 1/4° to 90°, a full list can be found in our catalog, and larger radii can be supplied. All elbows are supplied with plain ends; we offer an assortment of transition and termination fittings that can be installed on our elbows.

The Champion Duct® Joining System includes the interference joint, straight socket, gasket joint (triple seal), and tight lock joint plus adhesive and various sleeve couplings and adapters. To estimate the number of joints and adhesive cartridges necessary for your project, see our Epoxy Adhesive Calculator. For information on which joints to use by application and National Electrical Code (NEC) guidelines, visit our catalog. Champion Fiberglass can advise you on your joint purchase in relation to your project specs.

Champion Fiberglass offers split duct conduit for making field repairs when the cable cannot be removed. For more information on how and when to use split duct conduit, see our catalog.

Champion Fiberglass offers joints for Champion Duct®, Champion Flame Shield® and Champion Haz Duct® XW type conduit. Find out what joints are available by product line to suit your project needs and get more details.

The Champion Duct® Joining System includes the Interference Joint, Straight Socket, Gasket Joint (Triple Seal), And Tight Lock Joint plus various sleeve couplings and adapters. For information on which joints to use by application, and National Electrical Code (NEC) guidelines, visit our catalog. Champion Fiberglass can advise you on your joint purchase in relation to your project specs.

The Joining System for Champion Haz Duct® XW Type conduit includes the adhesive joint (the straight socket joint combined with epoxy adhesive), Straight Socket, and various alignment/expansion joint types, as well as various adapters and couplings. To estimate the number of joints and adhesive cartridges necessary for your project, see our Epoxy Adhesive Calculator.

The Phenolic Joining System includes the Adhesive Joint, which is the straight socket joint combined with the appropriate adhesive. The adhesive is applied to the spigot end of the conduit. To estimate the number of joints and adhesive cartridges necessary for your project, see our Epoxy Adhesive Calculator. Various straight socket expansion joints are also available; expansion fittings should be provided to compensate for thermal expansion and contraction. You can find more information on the Phenolic Joining System in our Champion Flame Shield® catalog.

With standard sizes of 3/4” x 10’ to 12” x 20’, you can find a full listing of available diameters and lengths in our catalogs: Champion Duct® Catalog.

The Phenolic Joining System includes the Adhesive Joint, which is the straight socket joint combined with the appropriate adhesive. The adhesive is applied to the spigot end of the conduit. To estimate the number of joints and adhesive cartridges necessary for your project, see our Epoxy Adhesive Calculator. Various straight socket expansion joints are also available; expansion fittings should be provided to compensate for thermal expansion and contraction. You can find more information on the Phenolic Joining System in our Champion Flame Shield® catalog.

The Joining System for Champion Haz Duct® XW Type conduit includes the adhesive joint (the straight socket joint combined with epoxy adhesive), Straight Socket, and various alignment/expansion joint types, as well as various adapters and couplings. To estimate the number of joints and adhesive cartridges necessary for your project, see our Epoxy Adhesive Calculator.

For information on which joints to use by application, and National Electrical Code (NEC) guidelines, visit our catalog. Contact us for assistance with your joint purchase in relation to your project specs.