When specifying electrical conduit there are a variety of metallic and non-metallic materials to choose from. GRC (or galvanized rigid steel conduit) and fiberglass conduit are two commonly used materials available today.

For many years steel was the material of choice for protecting cables and wires in industrial applications. Best known for its superior strength, the heavy weight and poor field handling of steel was often overlooked due a lack of other viable alternatives. Today, lower cost options like fiberglass (RTRC) can provide comparable strength with no burn-through, excellent field handling and significant overall project cost savings.

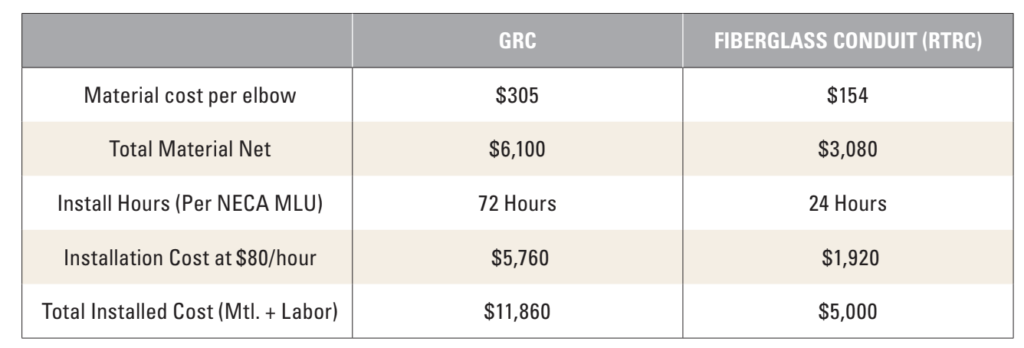

Traditionally, project managers and engineers turned to GRC or galvanized rigid steel conduit when applications required large quantities of conduit elbows, common in utilities projects and data center builds. The example below shows how close to 50% savings on materials can be achieved when switching from GRC to fiberglass, and at a quantity of twenty 4” elbows nearly 60% overall savings can be achieved on total project costs:

How? Champion Fiberglass® conduit elbows are lightweight which results in streamlined installation. They are UL-listed and feature high dielectric strength (550 volts) and low coefficient of friction, so there are no sacrifices made to efficiency or durability of the elbows when switching from galvanized steel. Champion Fiberglass also offers XW type conduit which can carry transition lines up to 125 KV.

Typically utilities projects can require miles of cable run. Champion Fiberglass conduit elbows offer a low coefficient of friction and no burn-through. Unlike other substrates (including PVC conduit), electrical contractors can be confident that fiberglass conduit won’t break when pulling through, which is especially important in large scale applications like data centers and utilities projects.

Fiberglass elbows are the only electrical conduit guaranteed not to melt or weld to the inside of the conduit, ensuring easy replacements and repairs as needed in the future. In the event of fault conditions galvanized rigid steel could cause the wire inside the conduit to weld to the conduit itself, an issue engineers never need to worry about with RTRC fiberglass conduit.

Unlike GRC, fiberglass conduit is a superior insulator, keeping installers safe from unfortunate electrical injuries. When you consider the value of safer installation, along with lower costs on material, freight and labor, it’s easy to see why more data centers are choosing fiberglass RTRC elbows over GRC.

Xpress Elbows – 48 Hour Shipping

Need elbows fast? Champion Fiberglass offers Xpress Elbows to get elbows shipped to customers within 48 hours when last-minute needs arise.

The program is available for orders of 100 pieces or less of popular sizes including:

- 12 radius 2” IPS x 90

- 24 radius 4” IPS x 90

- 36 radius 4/5/6” x 90

Choose from plain-ended, PVC deep-socket coupling transitions or PVC male and female adapter type transitions.

To learn more about the features and benefits of Champion Fiberglass no burn-through elbows, download the complete No Burn-Through Elbow Eguide.

To purchase RTRC conduit elbows today, reach out to your local Rep.