See What Makes Champion Strut™ a Superior Choice for Mechanical Engineers and Contractors

While traditional piping and conduit support options like steel and aluminum strut systems may be familiar, modern materials like fiberglass have made non-metallic alternatives a more attractive and practical solution for mechanical engineers and contractors. Today, many are finding that Champion Strut™ offers superior benefits across various industries and applications.

1. Lightweight Construction, Heavy-Duty Performance

Available in polyester and vinyl ester resin systems, Champion Strut is significantly lighter than traditional metallic strut systems. This makes it easier to transport, install, and handle on-site, resulting in fewer labor hours and quicker project completions. Despite its lightweight nature, Champion Strut™ doesn’t sacrifice durability—it’s strong enough to sustain even the most demanding environments.

Additionally, Champion Strut can be field-cut and drilled more easily than steel or aluminum, making on-site adjustments quick and efficient. This is a huge benefit for contractors who require flexibility during installation.

2. Superior Corrosion Resistance for Tough Environments

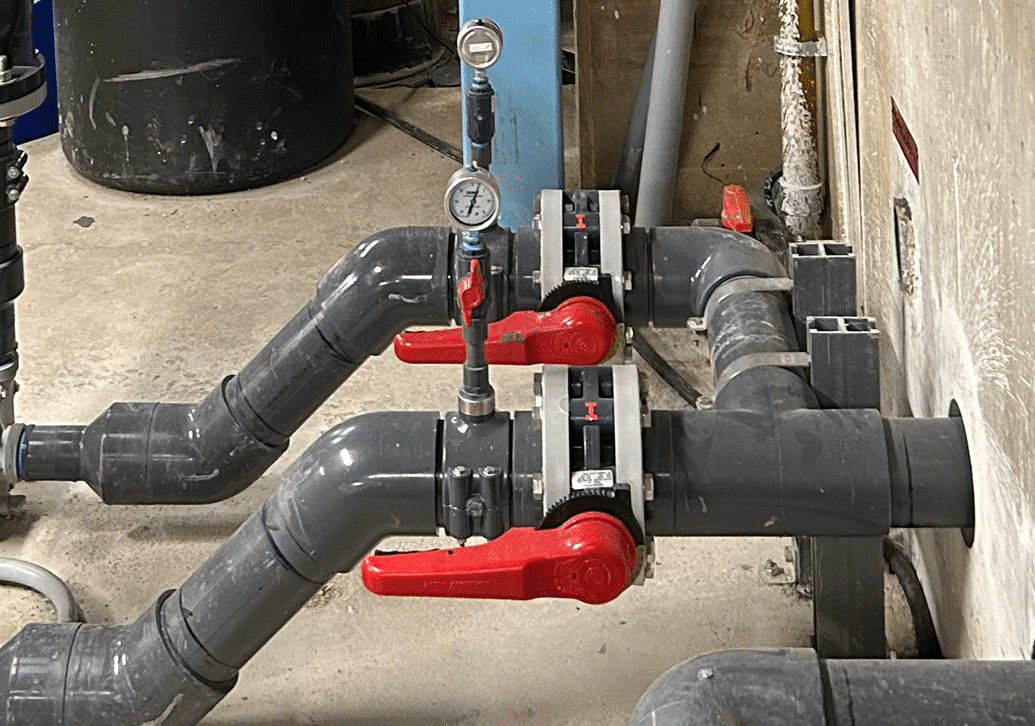

Steel and aluminum struts are prone to rust and degradation over time, especially in corrosive environments like coastal regions, chemical processing plants, petrochemical plants, or wastewater facilities. Champion Strut is made from corrosion-resistant, non-metallic materials, ensuring a long lifespan in challenging conditions where metallic struts would typically fail or require costly maintenance.

3. Wide Temperature Range for Versatile Applications

Engineered for extreme temperatures, Champion Strut can withstand a wide range of environmental conditions, making it suitable for both indoor and outdoor projects. Champion Strut offers temperature tolerances of:

- Polyester: -35°F to 200°F

- Vinyl Ester: -35°F to 200°F

- Polyurethane: -40°F to 140°F

4. Non-Conductive and Safe for Electrical Applications

Champion Strut eliminates the risks posed by conductive materials like steel aluminum, making it the ideal choice for data centers, utility projects, and other facilities where electrical conductivity could lead to safety hazards.

5. Compatible with Existing Systems

Champion Strut™ accommodates rigid steel pipe clamps (CS-SST Series), ensuring compatibility with existing systems and making it an easy upgrade for contractors.

Get the Stats

Download the complete comparison chart to see how Champion Strut provides a modern, high-performance alternative to steel and aluminum strut systems.

Ready to invest in a strut system that will outlast and outperform traditional materials, saving time, money, and headaches in the long run? Contact the Champion Fiberglass team directly at 281.655.8900 or info@championfiberglass.com.

Champion Fiberglass products are UL-listed and meet both NEC (National Electrical Code) and CEC (Canadian Electrical Code) standards. Champion Fiberglass conduit is BABA compliant.