From metal to PVC to fiberglass (RTRC), the electrical conduit market is loaded with players. Each electrical conduit system has distinctive properties that play out depending on the situation. When selecting rigid conduit, project considerations such as application and installation type play a role in determining the best product for a job.

Let’s take a look at how rigid metal conduit products GRC (galvanized rigid steel conduit) and PVC-coated steel stack up against fiberglass conduit.

Steel has a history of longtime use. It has been used since the turn of the last century for industrial, commercial and residential applications. The composition of steel provides adequate protection for raceway cables and wires. That protection comes at a price, though, and that is its heavy weight, poor field handling and significant price tag.

Fortunately, the electroindustry is recognizing the benefits of using lightweight-yet-strong fiberglass conduit (RTRC) in place of heavier, costlier conduit materials like GRC and PVC-coated steel to protect electrical wiring and cable. The advantages of fiberglass conduit that set it apart include light weight, cost savings, smooth installation and corrosion resistance.

A Weighty Issue

Lightweight conduit lowers overall project costs by reducing the costs of labor due to better portability in the field, contributing to a smoother, easier installation that takes less time. Project owners also tell us that they prefer fiberglass conduit on bridges and other raised platforms because it does not add as much weight to the overall load of the bridge.

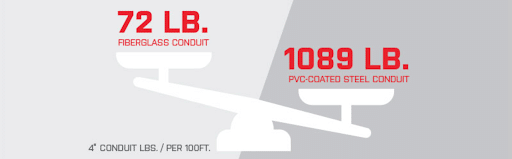

So let’s see how steel and fiberglass conduit types compare in weight across other electrical conduit systems. One hundred feet of 4” SW RTRC conduit weighs 72 pounds while the same 100 feet of galvanized rigid steel weighs in at 1030 pounds.

When comparing fiberglass versus steel conduit, GRC (galvanized steel) is not the heaviest conduit by any means. A look at PVC rigid coated steel reveals that PVC-coated steel carries the distinction of being the heaviest conduit in our comparison at 1089 pounds for 100 feet of 4” diameter conduit. That’s 15 times the weight of Champion Fiberglass conduit.

Material Cost Savings

Did you know that Champion Fiberglass is typically the most affordable conduit based on initial material costs? Overall project costs tend to be lower as well due to smooth, fast installation, mentioned previously.

Let’s take a closer look at initial material costs for fiberglass and steel conduit. Using our conduit calculator, we’re able to compare the same 4”, 10- foot piece of conduit across material types. Champion Fiberglass costs $594. Expressed as price per foot, that’s $5.94/ft.

Next, consider GRC. For the same 4”, 100-foot piece of conduit, GRC costs $17/ft., which means saving 65% when you choose fiberglass conduit over GRC.

Finally, PVC-coated steel conduit in the 4”, 100-foot piece costs $30/ft. Compared to fiberglass conduit, that comes to an 80% savings when specifying fiberglass conduit. It’s pretty easy to see the trend here that heavy conduit equals expensive conduit.

Streamlined Installation

We’ve illustrated the differentials in weight in the fiberglass vs. steel conduit comparison. Here’s how weight affects installation more specifically in terms of man-hours.

According to NECA Labor Installation Rates (normal installation man/hours per/100 ft), a 4” 100-foot length of GRC conduit takes 30 hours to install. The same size and length in PVC coated steel takes 38 hours to install. Fiberglass conduit installs in a fraction of the time for an equivalent size — 8.3 hours.

Strength & Durability

Think rigid fiberglass is weak? Think again. Fiberglass conduit is created by tension-winding strands of fiberglass over a rotating mandrel. The strands are laid in a precise pattern and impregnated with resin as they are wound onto a straight mandrel. They are then cured under high temperature, creating a conduit product with flexural strength and impact resistance that allows it to retain its shape. It has even been proven to stop bullets.

Corrosion Resistance

Fiberglass conduit is durable and able to withstand elements like salt water and UV light. Additionally, it is corrosion-resistant to over 70 chemicals, making it the preferred choice for conduit in applications like bridges, wastewater treatment, and chemical plants. Check out the extensive list of chemicals our conduit has been tested against.

Competitive Pricing, Short Lead Times

Champion FIberglass is a reliable alternative to PVC-coated steel with the added bonus of not being subject to the current PVC shortage. Our conduit is proudly made in America from epoxy fiberglass. So if PVC product delays are causing headaches, you can trust Champion Fiberglass conduit as an exceptional conduit substitute.

Are Fiberglass and Steel Conduit The Only Options?

Other types of conduit include flexible metal conduit (FMC), electrical metallic tubing (EMT) and electrical nonmetallic tubing (ENT).

Unlike flexible metal conduit or FMC, electrical metallic tubing (EMT) is known to be a lighter and cheaper alternative to GRC. Electrical nonmetallic tubing (ENT) is a corrugated flexible conduit that is used for electrical raceways. It can be installed in concrete slabs, fire-rated interior walls or directly buried. Review your project requirements to determine the best electrical conduit material for your job.

Used across many applications, Champion Fiberglass conduit remains the best choice compared to GRC, PVC-coated steel, FMC, EMT and ENT due to its strength and durability, light weight, cost savings and ease of installation across many applications including transportation/DOT, utilities and wastewater treatment.

Keep Reading

Champion Fiberglass® Named a CompositesWorld Top Shop for 2024

The origins of fiberglass date back to the ancient Greeks. Today fiberglass is used for a variety of applications from…

Get to Know Research and Development Engineer Blake Rogers

He’s got a diverse background in engineering, is new to Texas and can juggle. Meet Blake Rogers.

Electrical Conduit Cost Savings: A Must-Have Guide for Engineers & Contractors

To help identify cost savings that don’t cut corners on quality, Champion Fiberglass developed a free resource for engineers and…