Application Overview

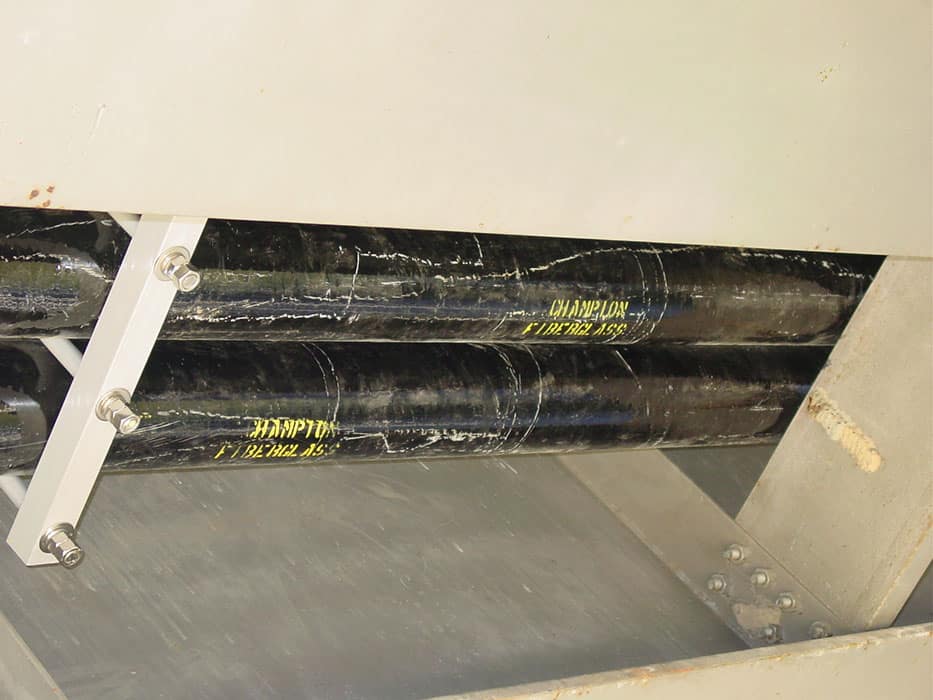

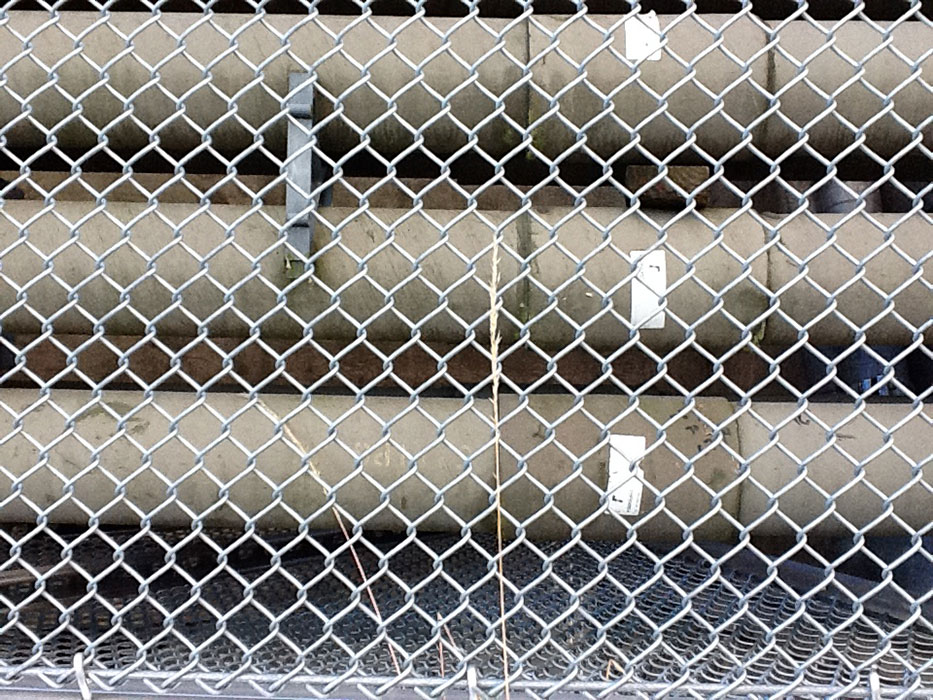

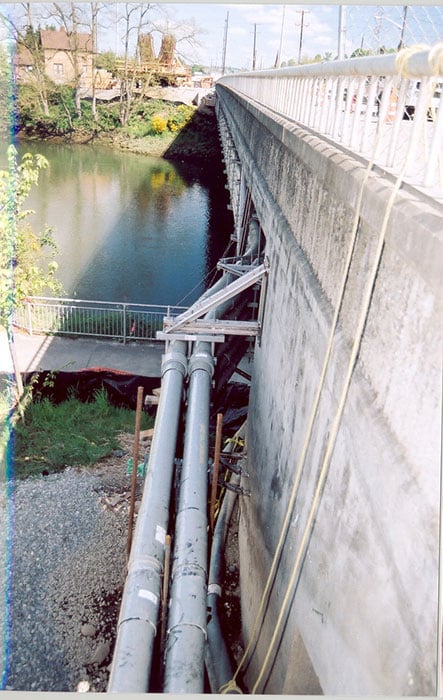

Champion Fiberglass has been providing conduit systems for bridge projects for decades. From custom-colored conduit for Pittsburgh’s Seventh Street Bridge to the Blue Water Bridge in Canada to the Golden Gate Bridge, we’ve completed thousands of bridge projects in the transportation/infrastructure sector. We’ve been supplying durable, cost-effective, American-made electrical conduit for more than 30 years. As a result, electrical engineers increasingly rely on our fiberglass (RTRC) conduit when bridge projects require a lightweight, easy-to-install, corrosion-resistant conduit system.

Featured Video

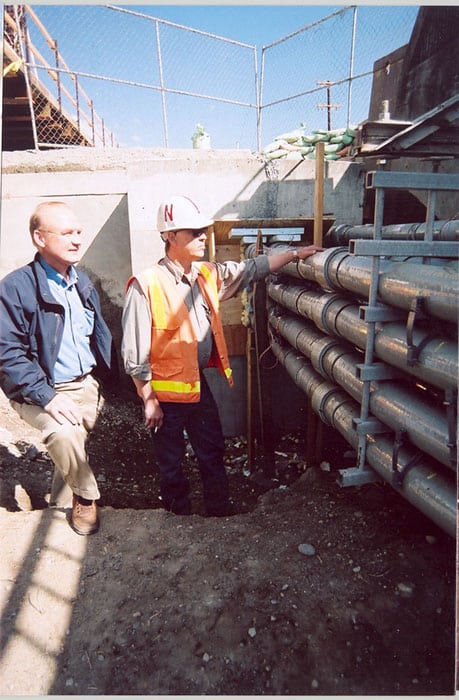

Bridge Hangers & Fiberglass Conduit Duct – Installation Guide

Our new Bridge Hanger animation demonstrates how fast and easy it is to install light, sturdy fiberglass conduit onto bridges.

Why?

Epoxy Fiberglass (RTRC) conduit is lighter and less costly than galvanized rigid steel conduit (GRC) and PVC coated rigid metal conduit options. RTRC also offers best in class field handling due to its light weight, ease of cutting and integral bell, making it the clear choice for bridges and state DOT (Department of Transportation) projects.

Electrical Conduit for Bridge Projects

Bridge projects call for lightweight conduit that doesn’t sacrifice strength. Champion Fiberglass conduit keeps these projects on budget and lowers manpower costs with durable, corrosion-resistant conduit.

Featured Product

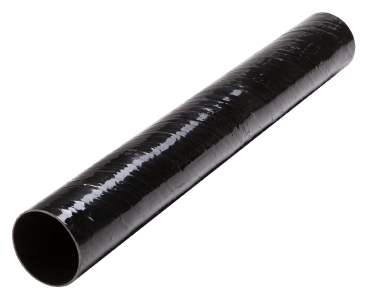

Champion

Duct

Lightweight fiberglass conduit with unmatched versatility and strength.

- CSA listed per CSA-22.2 No 211.3-96 standards

- UL 2420 Listed for below-ground installations

- UL 2515 Listed for above and below-ground installations

- Standard Wall, Medium Wall (UL designates Champion Fiberglass MW for 5″ and 6″ as SW), and Heavy Wall conduits are UL Listed for newly expanded support spacing distances

Champion Fiberglass products are manufactured in accordance with the NEC (National Electrical Code) in Article 355: Reinforced Thermosetting Resin Conduit and listed in Article 12-200 of the CEC (Canadian Electrical Code) as Rigid RTRC Conduit.