CHAMPION STRUT

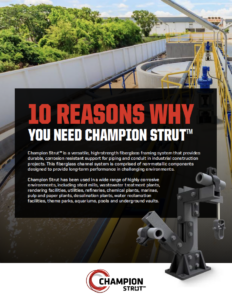

Champion Strut is a fiberglass non-metallic channel framing system that includes a complete line of non-metallic accessories, fasteners, hangers, pipe clamps and channels. Champion Strut is a versatile, high-strength fiberglass framing system that has been successfully used in many highly corrosive applications including steel mills, wastewater treatment, rendering facilities, utilities, refineries, chemical plants, marinas, pulp and paper, desalination facilities, water reclamation facilities, theme parks, aquariums, pools and underground vaults.

CHAMPION STRUT

ADVANTAGES

For long-lasting project performance, Champion Strut is a complete system of fiberglass channel & non-metallic components.

Features

These components include fittings, threaded rods, pipe clamps, fasteners, nuts and accessories, pipe and conduit hanger types, pipe hanging accessories, as well as wall support racks for framing and mounting conduit and mechanical piping. The channels are supplied in standard 10-foot lengths.

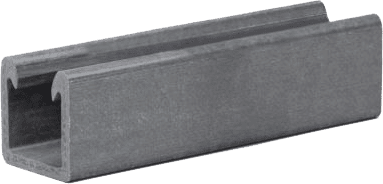

- Multiple strut channel profiles to accommodate any application

- Non-metallic – available in both polyester (dark grey) and vinyl ester (beige) resin systems

- A complete line of corrosion-resistant fiberglass components provides durability and contribute to project longevity

- UV resistant – fiberglass channels incorporate UV inhibitors and surfacing veil which improves weatherability and inhibits UV degradation

- Fire retardant for added protection

- Lightweight for smooth and fast installation

- Easy to field cut and drill – Supplied in standard 10-ft lengths with 20-ft lengths available upon special-order request

- CS-SST Series Channel (only) will accommodate rigid conduit steel pipe straps

- Customization, such as special colors, available upon request

For assistance, contact Champion Fiberglass for proper selection.

DATA SHEETS

Champion Strut

Industries

Champion Strut is a versatile, high-strength fiberglass framing system that has been successfully used in many highly corrosive applications including steel mills, wastewater treatment, rendering facilities, utilities, refineries, chemical plants, marinas, pulp and paper, desalination facilities, water reclamation facilities, theme parks, aquariums, pools and underground vaults.

Champion Strut

Engineering

All of the strut and most of the fittings are manufactured by the pultrusion process, where continuous strands and mats of glass fiber are immersed in the resin and then pulled through a heated die. Many different shapes can be manufactured by this process. Special UV additives along with a polyester surfacing veil are added to give the components increased UV and corrosion resistance.

Fiberglass conduit is listed in Article 12-200 of the CEC (Canadian Electrical Code) as Rigid RTRC Conduit.

You’ll find it listed in the NEC (National Electrical Code) in Article 355 as Reinforced Thermosetting Resin Conduit.

A 100% DIGITAL FACILITY THAT STRIVES TO MEET ENVIRONMENTAL AND SYSTEM MANAGEMENT REQUIREMENTS

- ISO 9001 – Certified in quality management systems for over a decade

- ISO 14001 – World’s premier environmental management certification

- ISO 45001 – Certified occupational health and safety management systems

Champion Strut

Catalog and Info

The Champion Fiberglass Strut catalog is available for download or to review online.

FAQ

Customization, such as special colors, are available upon request. Light grey colored polyester channel is available with a special part number. As for special lengths, 20-ft lengths may be requested.

Champion Strut lead-times range from stock on most all items to longer depending on the item and number of parts required. Please contact Champion Fiberglass for the availability for any strut items.

The Champion Strut® fiberglass framing system has been successfully used in many highly corrosive applications including steel mills, wastewater treatment, utilities, chemical plants, and desalination facilities. It’s also contributed to safe, secure, stable installations in rendering facilities, refineries, marinas, pulp and paper plants, water reclamation facilities, theme parks, aquariums, pools and underground vaults.