Champion Fiberglass® values innovation. The company places a premium on research and development in order to create high-performance products for customers. An example of this is the launch of two new product lines — Champion Bridge Drain™ and Champion Strut™ — last year.

A key component of this initiative is the purchase of new, leading-edge equipment for the fiberglass manufacturing floor. This year Champion Fiberglass made investments in equipment that provides better efficiency and quality in our manufacturing process.

This investment helps us fulfill our promise to Do More for customers, employees, and the industry. We are able to innovate and fabricate more efficiently to get products in the hands of customers faster.

Allow us to take you around the plant for a tour of recent acquisitions.

Our new plasma cutting machine cuts materials, mostly metals such as steel. It helps us provide precision, quality, and speed in fabricating component parts and electrical conduit fittings on our manufacturing floor.

Its main benefit is time savings. With this piece of machinery, we’re able to create quality component parts faster, which benefits customers with faster turnaround times.

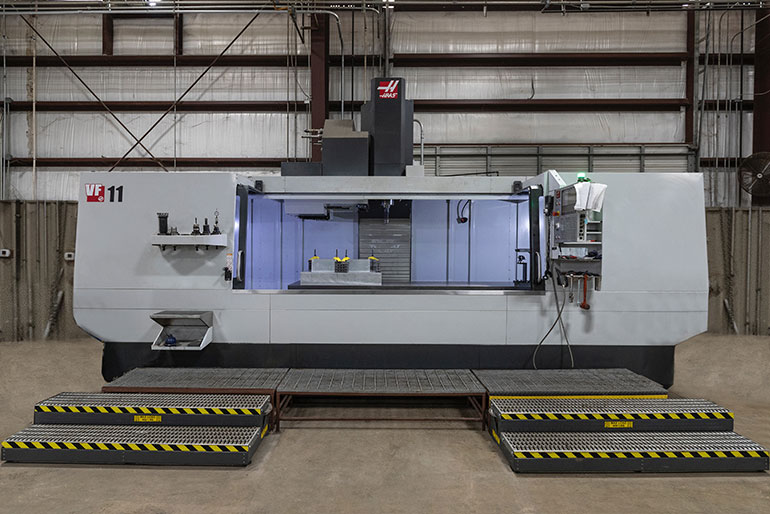

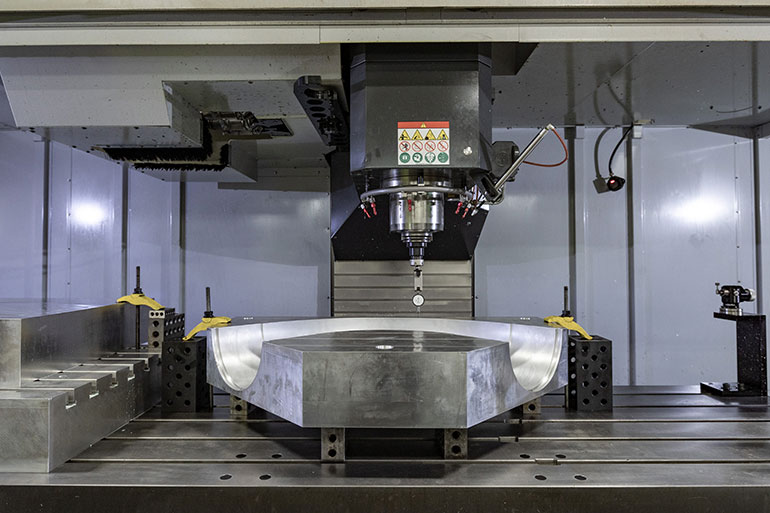

The CNC milling machine, made by US company Haas, is an enormous piece of machinery, about the size of a small trailer, that provides more capacity in production. It is a 40 horsepower, computerized machine that creates and cuts shapes and parts, such as molds, programmed from renderings in AutoCAD. It runs 24 hours and fabricates Champion Bridge Drain™ parts.

Our investment in the CNC Milling machine allows us to create in-house what most companies go abroad to supply. We are able to produce these parts for half the cost in half the time. This machine is a win-win for customers, because not only does it create quality parts, it does so faster and at a lower cost than overseas manufacturers, saving customers time and money so they can complete projects efficiently. The fact that Champion Fiberglass has made key investments in manufacturing machinery such as this really sets the company apart from other conduit manufacturers.

Equipment Investments Benefit Customers

Champion Fiberglass values innovation, and research and development that allow for more efficient manufacturing. These equipment investments allow Champion Fiberglass to effectively create quality, cost-efficient electrical conduit, bridge drainage, and strut products from our leading-edge manufacturing facility in Texas.

Because our products are Made in the USA, they are more readily available with shorter lead times, lower prices and better quality than similar products produced overseas. Finally, we’re able to pass along benefits and savings to customers because we fabricate more efficiently and effectively.

Get in touch to see how our conduit, strut, and bridge drainage products can enhance your projects.

Keep Reading

Champion Fiberglass® Named a CompositesWorld Top Shop for 2024

The origins of fiberglass date back to the ancient Greeks. Today fiberglass is used for a variety of applications from…

Get to Know Research and Development Engineer Blake Rogers

He’s got a diverse background in engineering, is new to Texas and can juggle. Meet Blake Rogers.

Electrical Conduit Cost Savings: A Must-Have Guide for Engineers & Contractors

To help identify cost savings that don’t cut corners on quality, Champion Fiberglass developed a free resource for engineers and…