Application Overview

Few industrial environments are more caustic or damp than wastewater treatment facilities. Harsh chemicals, extreme temperatures and aging infrastructure require strong, durable conduit systems. That’s why Champion Fiberglass® epoxy fiberglass conduit does more to stand up to the challenges of a highly corrosive environment.

In the US, more than 14,000 wastewater treatment plants provide critical infrastructure required to maintain public health. When specifying conduit for wastewater projects and sewer systems, corrosion resistance is key. At $36 billion annually, the cost of corrosion related to water and sewer systems is big business.

Featured Video

Watch the Wastewater Treatment Video

Champion Fiberglass does more to stand up to the challenge in damp and corrosive environments. With lightweight, non-corrosive fiberglass construction, Champion Fiberglass is the right choice to keep your operations safe-and your conduit installations intact over the long-term.

Electrical Conduit for Wastewater Plants

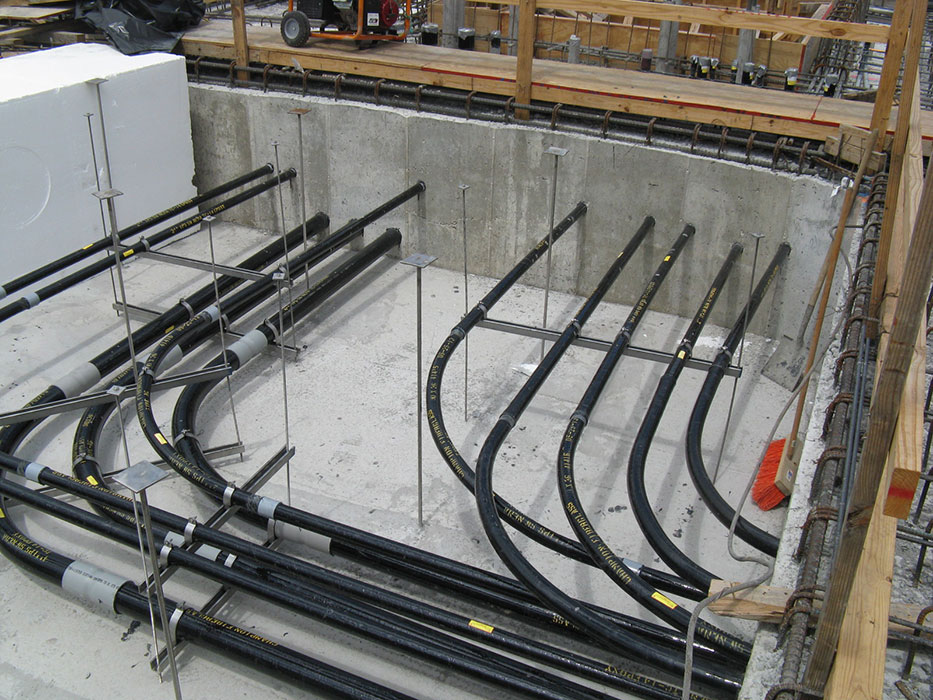

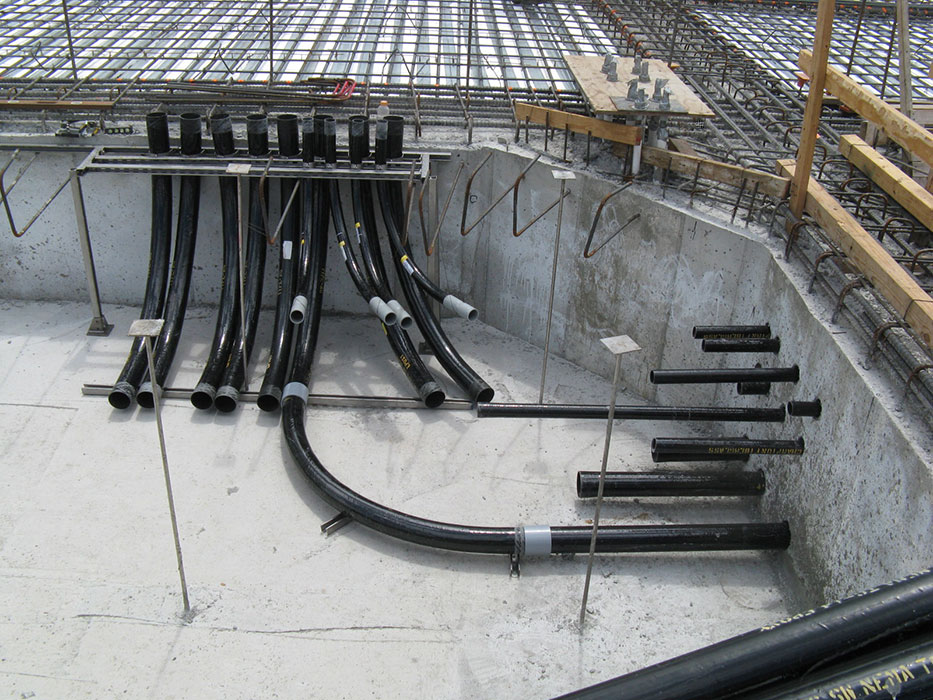

Understanding environmental contaminants and chemical processing is key to selecting a conduit for a wastewater treatment plant project. Sodium hypochlorite (bleach), polymer wastewater sludge, liquid oxygen, and waste activated sludge can all threaten the integrity of electrical conduit systems. Champion Fiberglass (RTRC) conduit is resistant to a wide variety of chemicals.

Costly replacements and repairs can eat up a significant portion of a wastewater facility’s budget. Among the types of conduits in environmental engineering, fiberglass (RTRC) conduit offers a cost-effective, long-term solution.

Traditional materials including stainless steel conduit and PVC coated conduit are significantly heavier than epoxy fiberglass, contributing to higher installation costs per the NECA Manual of Labor Units. When considering the combined cost of material and labor, RTRC costs 71% less than aluminum conduit and provides comparable protection in corrosive atmospheres.

Innovative Solutions for Highly Corrosive Environments

In the case of Fox Metro Wastewater Treatment Plant, the existing conduit system began to fail when a large portion of the PVC coating had begun separating from the underlying rigid steel conduit itself, allowing corrosion to take place. Champion Fiberglass created a custom conduit solution for the plant measuring 8,000 feet to ensure the plant could meet federal and state quality standards and continue to serve nearly 300,000 residents and business stakeholders.

With lightweight, non-corrosive fiberglass construction, Champion Fiberglass is the right choice to keep your operations safe and your conduit installations intact over the long-term.

Featured Product

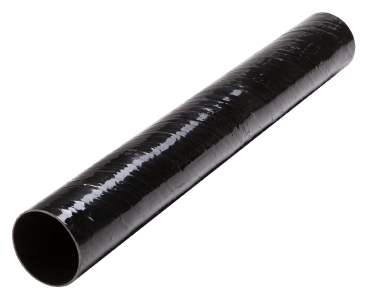

Champion

Duct

Lightweight fiberglass conduit with unmatched versatility and strength.

- CSA listed per CSA-22.2 No 211.3-96 standards

- UL 2420 Listed for below-ground installations

- UL 2515 Listed for above and below-ground installations

- Standard Wall, Medium Wall (UL designates Champion Fiberglass MW for 5″ and 6″ as SW), and Heavy Wall conduits are UL Listed for newly expanded support spacing distances

Champion Fiberglass products are manufactured in accordance with the NEC (National Electrical Code) in Article 355: Reinforced Thermosetting Resin Conduit and listed in Article 12-200 of the CEC (Canadian Electrical Code) as Rigid RTRC Conduit.