When looking for conduit that offers high quality and high performance at a lower cost, fiberglass conduit comes out ahead in a variety of applications. Due to its naturally corrosion resistant composition and lower coefficient of friction, fiberglass conduit has quickly become the choice of electrical engineers representing challenging applications such as wastewater treatment, pipelines, and data centers.

In addition to its impressive durability and cost effectiveness, fiberglass conduit offers a streamlined installation process. A lighter weight contributes to optimum field handling, while a lower coefficient of friction enables longer cable runs. When comparing fiberglass conduit to conventional rigid conduit materials, fiberglass equals project speed, quality, and savings.

Here are three more applications in which fiberglass conduit is providing big solutions to big challenges:

Utilities

In addition to longer underground wire pulls, the non-conductive properties of fiberglass conduit enhance safety by reducing cable and electrical fault hazards. Also, substations that use fiberglass elbows don’t experience burn through.

Case Study: When PVC conduit was specified to use along a two-mile duct bank for a coal-burning plant in Indiana, the engineers knew they needed a material with a lower coefficient of friction and opted to use Champion Fiberglass conduit instead. This made it possible to extend the concrete vaults by up to 750 ft., eliminating the need for several concrete vaults, which resulted in a projects savings of $3 million.

Case Study: A major Southeast Texas utility was facing cable and copper theft at an alarming 10,000 ft. per month When galvanized steel was rejected as too heavy and expensive to replace the burglarized PVC pole risers, the client turned to Haz Duct® XW conduit from Champion Fiberglass. This tough, lightweight solution has not only deterred vandalism, its composition has withstood coastal environmental conditions, and it is now the go-to solution for all their pole risers.

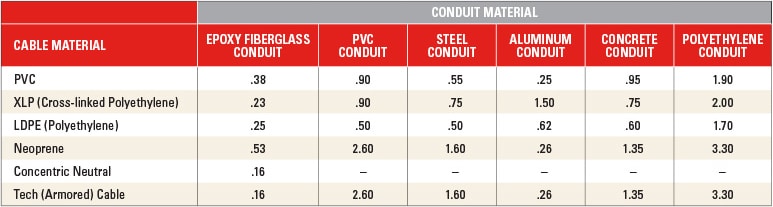

Coefficient of Friction

The following data for static coefficient of friction is for dry conduit and non-lubricated cable at a temperature of 72° F (22° C).

Stadiums

Whether it’s lights, technology, or activity, the stadium experience requires a tremendous amount of energy. Traditionally, these settings have opted for GRC (galvanized rigid steel) conduit. However, fiberglass conduit offers the same protection with the added advantage of being lighter in weight, making for easier handling and faster installations. And because of the lower coefficient of friction and integral bell for smooth connection joints without gaps, fiberglass conduit is ideal for the unique electrical wiring needs of stadiums.

Case Study: Texas A&M had a two-month deadline in which to find and install a quick, effective solution to upgrade its aging circuit system. Steel was disregarded due to delivery times – instead, the client opted for fiberglass conduit. Champion Fiberglass was able to offer quick installation and save the school about 10% in material costs, coming in ahead of their target timeline. Kyle Field was ready to host 50,000 fans to cheer on the Aggie football team.

Interference Joint

The interference joint system consists of an integral bell and spigot. The spigot end has a buttress type, male thread for easy installation.

Stadiums all around the country use fiberglass conduit, including the Atlanta Falcons’ Mercedes-Benz Stadium, the Minnesota Vikings’ U.S. Bank Stadium, the University of Michigan’s Michigan Stadium and Ohio State’s Ohio Stadium.

Chemical Plants

In an environment where safety is the #1 priority, the hazardous rating of fiberglass conduit makes it an ideal choice. PVC materials release toxic halogens when burning, including chlorine and bromine – harmful to employees, the public, and emergency personnel alike. However, Champion Haz Duct® XW Type Fiberglass Conduit is a Class I, Div 2-rated conduit system, suitable for chemical plant projects and impervious to chlorine fumes which may be present in these environments. Fiberglass is the safer solution in extreme conditions and should be considered as the conduit of choice for chemical plants.

Toxicity

Champion Duct conduit does not contain any compounds that can release halogens –

bromine or chlorine – when burning.

Big Challenges, Big Solutions

With greater durability and shape retention than PVC, and at lighter weight and lower cost than steel, high-performance fiberglass conduit from Champion Fiberglass is safe, efficient, and proven to save companies millions. Learn more today about why it’s the best choice for commercial and industrial applications.