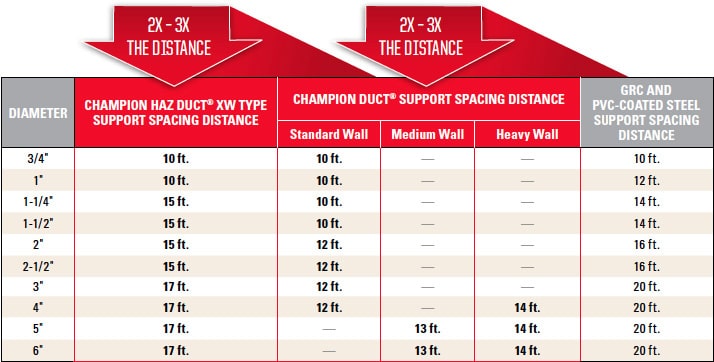

In 2016, Champion Fiberglass brought expanded support spacing distances to UL-Listed Haz Duct® XW Type Conduit. In 2017, Champion Duct® Standard Wall (SW), Medium Wall (UL designates Champion Fiberglass MW for 5″ and 6″ as SW) and Heavy Wall (HW) conduit also featured expanded support spacings, making the support span distances of these conduit products comparable to those of GRC and PVC-coated steel. Read more about how Champion Fiberglass worked to advance the code that allowed these expanded support spans in our previous blog.

But in comparing the savings inherent in Champion Fiberglass conduit to GRC and PVC-coated steel, there are other factors and benefits to weigh. Champion Fiberglass has not only put together a guide to these factors, but now offers a Conduit Calculator that allows you to make your own comparisons.

Comparison – benefits overview

First, we must look at the properties of GRC and PVC-coated steel.

GRC/RMC is the heaviest-weight and thickest-wall steel conduit, and corrosion resistance is achieved via a zinc coating. This coating may be applied on both the conduit’s interior and exterior, or on the interior only. Couplings are mechanical, with threads on the uncoupled end, and screws holding connectors in place—contributing to substantial installation time requirements. Although it has been considered the highest level of mechanical protection, it does not retain/return to its original shape after impact or damage.

PVC-coated steel features the same weight as GRC conduit, making it one of the two heaviest conduit options and contributing to poor field handling. When burning, it releases toxic halogens – fiberglass (RTRC) does not. PVC-coated steel performs poorly in UV stability (per UL 2515 and CSA C22.2 No. 211.3-96). PVC-coated steel conduit does not retain its original shape after impact.

Compare to Champion Fiberglass conduit’s properties:

Coating

Constructed of glass filaments impregnated with resin, then cured. No extra coating necessary.

Flexural strength

Retains its original shape after impact or compression.

Corrosion resistance

Corrosion resistance is built into the conduit material; features the broadest range of corrosion resistance of all in-market conduit materials.

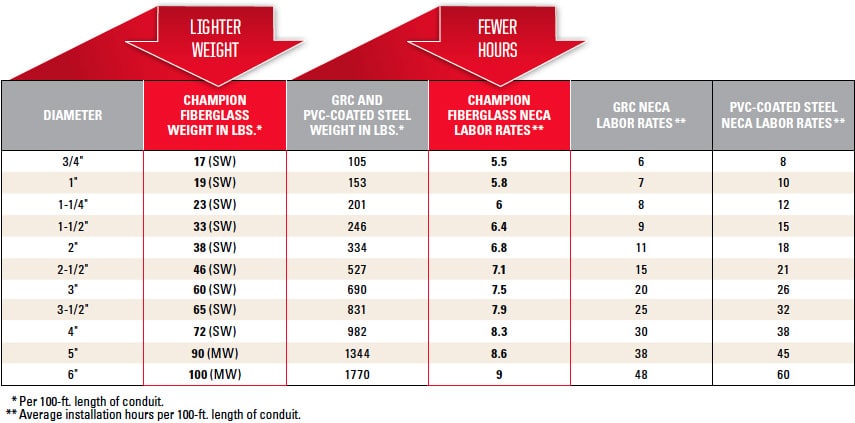

How weight and installation times affect your bottom line.

The following charts compare Champion Fiberglass conduit to GRC and PVC-coated steel, taking into account support spacing distances, weight, and time to install. The most favorable results for each diameter (weight and labor rates) have been highlighted.

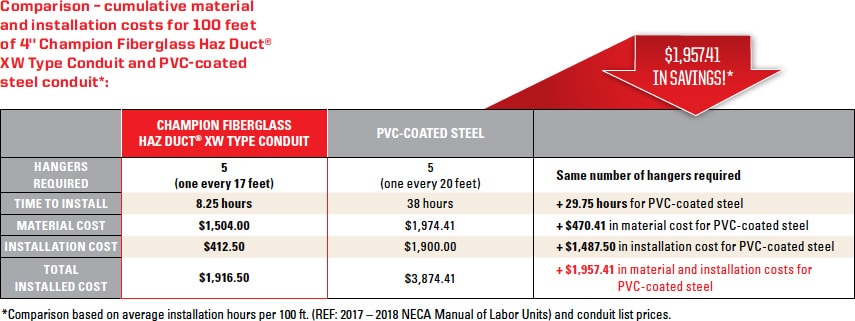

We did the math.

When considered together, the above benefits add up to considerable savings. Using our Conduit Calculator, we did the math for an installation using 4″ diameter Haz Duct® conduit to provide a point of reference for the savings available when you specify Champion Fiberglass conduit.