As a building material, electrical conduit is used in a wide range of applications across industrial construction, from bridges and data centers to utilities and wastewater treatment plants, where it serves to organize and protect cables and wires in raceways. Conduit provides mechanical protection, and caustic environments demand corrosion protection through chemical resistance.

In the US, close to 15,000 wastewater treatment plants provide the critical infrastructure required to maintain public health. With extreme chemicals and unrelenting temperatures, it’s a damp and caustic environment with maintenance and construction that demands durable materials.

If electrical conduit does not provide ample chemical resistance, it fails to provide corrosion protection, leaving the conduit, wire and cable subject to compromise. Subsequently, a compromised conduit and cable system has the potential to impact municipal water supplies.

What is Chemical Resistance?

Chemical resistance is the ability of a material to resist the destructive properties of harsh compounds without degrading. In industrial construction, there’s exposure to thousands of chemical compounds, and some of the more common include saltwater, petrochemicals and bleach. Think of chemical resistance as strength to resist a chemical attack. Simply put, electrical conduit chemical resistance equals corrosion protection.

Why does epoxy chemical resistance matter?

Engineers and contractors have a wide array of electrical conduit materials to select from for industrial projects. Depending on the project needs, conduit types to choose from include galvanized rigid steel (GRC), PVC SCH 40, PVC SCH 80, PVC-coated steel, aluminum conduit and epoxy fiberglass conduit.

While PVC electrical conduit is often the choice for corrosive environments, fiberglass conduit provides similar chemical protection. Plus, it is not subject to the current PVC shortage. Fiberglass electrical conduit is available now with shorter lead times and competitive pricing.

Fiberglass conduit is a wise choice for harsh, challenging environments because of its epoxy chemical resistance. This is due in part to its unique fabrication processes.

Fiberglass conduit is created by tension-winding strands of fiberglass over a rotating mandrel. The strands are laid in a precise pattern and impregnated with epoxy resin as they are wound onto a straight mandrel. They are then cured under high temperature, creating a conduit product with flexural strength that also resists chemicals and corrosion. This process ensures that fiberglass conduit comprised of epoxy resin is much more corrosion resistant than PVC conduit and polyester and vinyl ester resins.

Fiberglass Chemical Resistance Guide Illustrates Corrosion Testing Results

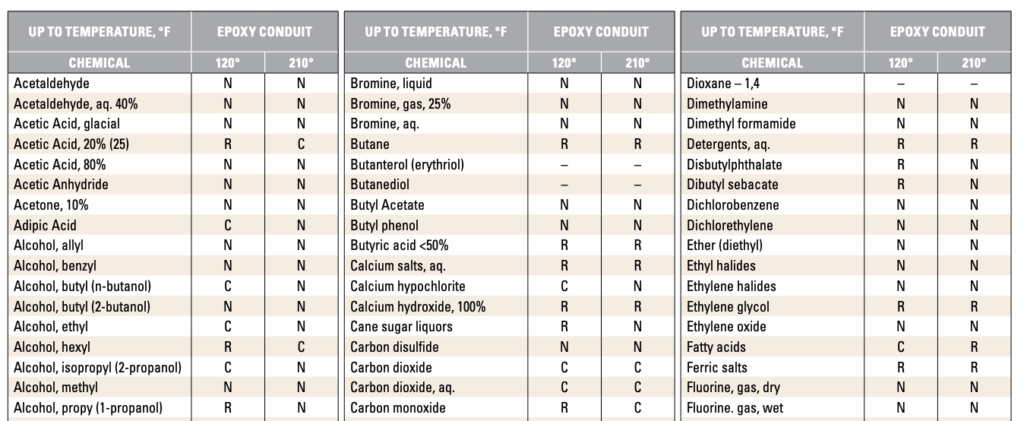

Champion Fiberglass® conduit has been tested with strict protocols against hundreds of chemicals. Our Chemical Resistance Guide documents epoxy chemical test results in a chart format.

The corrosion guideline tests were performed by immersing epoxy coupons for 30 days in each chemical at designated temperatures. A very severe test, it has been shown that Champion Duct® can often be used for chemicals listed as “Not Recommended” (NR) as real cases often are limited to fumes, vapors and occasional splashes at the temperatures indicated.

(The information provided in the epoxy chemical resistance chart is to be used solely as a guide since it is impossible to anticipate all individual site conditions. For specific applications which are not covered in this guide, and may require screening tests to evaluate resin system suitability, consultation with Champion Fiberglass is recommended.)

Harsh Environments Demand a Corrosion Resistant Electrical Conduit

Manufactured for strength and durability and supported with impressive corrosion testing results, Champion Duct® and Champion Haz Duct® have demonstrated performance in harsh applications that demand a chemically resistant material.

Champion Duct® electrical conduit has been used successfully in wastewater treatment projects to provide ultimate protection against corrosive chemicals such as hydrogen sulfide, hydrochloric acid and sulfuric acid.

For especially harsh situations, Champion Haz Duct® is constructed to handle the demands of volatile industrial environments. Its thicker walls provide enhanced flame resistance with low-smoke characteristics, offering solid performance in even the most hazardous surroundings.

For additional epoxy resin technical data and related fiberglass (RTRC) spec sheets, find data sheets and information.