By Scott Patchan

Conduit support spacing refers to the maximum distance between support points when installing electrical conduit systems. Choosing conduit that allows longer spacing can drastically reduce material and labor costs, especially on large-scale projects.

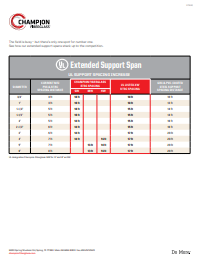

- NEC conduit support requirements permit extended spans for UL‑listed Champion Fiberglass® RTRC (Reinforced Thermosetting Resin Conduit), reducing labor and material costs.

- Cost saving conduit spacing can cut supports by 50–70%, translating to significant savings on large projects.

- XW, SW, MW, and HW conduit types offer spacing comparable–or superior–to steel GRC and PVC-coated steel conduit.

- UL‑listed RTRC spans match or exceed GRC (galvanized rigid conduit) thanks to rigorous UL/NEC updates dating back to 2016.

Champion Fiberglass® and NEC Conduit Support Spacing Requirements

Electrical conduit support spacing can have a significant effect on overall project costs, due to the number of supports required as well as the time to install the complete conduit system. In 2016, Underwriters Laboratories (UL, now known as UL Solutions) updated the National Electric Code related to RTRC support spacings to reflect longer support spacing distances for Champion Haz DuctⓇ XW Type conduit. In 2017, Champion Duct® Standard Wall (SW), Medium Wall (with UL classifying 5″ and 6″ MW as SW), and Heavy Wall (HW) conduit systems achieved updated UL support spacing listings. These revised listings effectively closed the support spacing differential relative to GRC and PVC-coated steel conduit, thereby enhancing the structural equivalence and installation efficiency of fiberglass conduit for industrial applications.

Champion Fiberglass actively collaborated with UL and the National Electrical Code (NEC) to extend allowable conduit support distances across product lines, including extensive independent testing conducted by UL to determine that Champion Fiberglass conduit met the requirements of the National Electrical Code (NEC) Article 355.30 for Securing and Supporting before extending its support spacing distances.

Champion Fiberglass remains the only fiberglass conduit manufacturer with UL‑listed extended support spans.

Why Lighter & Fewer Supports Matter

- Easier handling: Lighter weight means safer, quicker installations.

- Economic impact: Fewer supports and man-hours can dramatically reduce project timelines and labor costs.

Conduit Weight Comparison

(SW IPS – lbs/per 100 ft)

Fiberglass conduit offers the lowest weight and is still very rigid.

| Epoxy Fiberglass | PVC SCH 40 | PVC SCH 80 | Galvanized Rigid Steel | PVC-Coated Steel | Aluminum | |

|---|---|---|---|---|---|---|

| 3/4″ | 17* | 23 | 29 | 105 | 105 | 36 |

| 1″ | 19* | 34 | 43 | 153 | 153 | 53 |

| 1-1/4″ | 23* | 46 | 59 | 201 | 201 | 70 |

| 1-1/2″ | 33* | 55 | 99 | 246 | 246 | 86 |

| 2″ | 38* | 73 | 99 | 334 | 334 | 116 |

| 2-1/2″ | 46* | 125 | 152 | 527 | 527 | 183 |

| 3″ | 60* | 164 | 212 | 690 | 690 | 239 |

| 3-1/2″ | 65* | 198 | 262 | 831 | 831 | 288 |

| 4″ | 72* | 234 | 310 | 982 | 982 | 340 |

| 5″ | 120** | 318 | 431 | 1344 | 1344 | 465 |

| 6″ | 142** | 412 | 592 | 1770 | 1770 | 612 |

*SW **MW

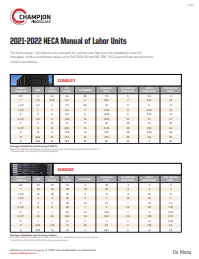

NECA Labor Installation Rates

(Normal installation man/hours per/100 ft)

(REF: 2024-2025 NECA Manual of Labor Rates)

| Epoxy Fiberglass | PVC SCH 40 | PVC SCH 80 | Galvanized Rigid Steel | PVC-Coated Steel | Aluminum | |

|---|---|---|---|---|---|---|

| 3/4″ | 5.5 | 4.5 | 5.4 | 6.0 | 8.0 | 5.5 |

| 1″ | 5.8 | 5.3 | 6.3 | 7.0 | 10.0 | 6.0 |

| 1-1/4″ | 6.0* | 6.0 | 7.2 | 8.0 | 12.0 | 6.5 |

| 1-1/2″ | 6.4* | 7.0 | 8.4 | 9.0 | 15.0 | 7.0 |

| 2″ | 6.8* | 8.0 | 9.6 | 11.0 | 18.0 | 8.0 |

| 2-1/2″ | 7.1* | 9.0 | 10.8 | 15.0 | 21.0 | 10.0 |

| 3″ | 7.5* | 10.0 | 12.0 | 20.0 | 26.0 | 12.0 |

| 3-1/2″ | 7.9* | 12.0 | N/A | 25.0 | 32.0 | 15.0 |

| 4″ | 8.3* | 14.0 | 16.8 | 30.0 | 38.0 | 19.0 |

| 5″ | 8.6* | 18.0 | 21.6 | 38.0 | 45.0 | 24.0 |

| 6″ | 9.0* | 24.0 | 28.8 | 48.0 | 60.0 | 30.0 |

*Reduce labor units by 10% for 20-foot lengths

Selecting the Right Wall Thickness

- SW (Standard Wall): 0.070″ wall; typical for ¾″–4″; UL 2515 (above ground) and UL 2420 (below ground) listed.

- MW (Medium Wall): 0.096″; UL 2515 (above ground) and UL 2420 (below ground) listed.

- HW (Heavy Wall): 0.110″; UL 2515 (above ground) and UL 2420 (below ground) listed.

- XW (Extra Heavy Wall): 0.250″; UL listed for Class I, Division 2 hazardous environments and high-impact areas.

How Does Champion Fiberglass Conduit Support Spacing Compare to GRC?

The chart below shows a comparison of Champion Fiberglass XW conduit to GRC (Galvanized Rigid Conduit) support spans:

| Current NEC, PVC & RTC Spacing | SW* | MW* | HW* | XW* | GRC, PVC-Coated & Aluminum Spacing | |

|---|---|---|---|---|---|---|

| 3/4″ | 3 ft | 10 ft | – | – | 10 ft | 10 ft |

| 1″ | 3 ft | 10 ft | – | – | 10 ft | 12 ft |

| 1-1/4″ | 5 ft | 10 ft | – | – | 15 ft | 14 ft |

| 1-1/2″ | 5 ft | 10 ft | – | – | 15 ft | 14 ft |

| 2″ | 5 ft | 12 ft | – | – | 15 ft | 16 ft |

| 2-1/2″ | 6 ft | 12 ft | – | – | 15 ft | 16 ft |

| 3″ | 6 ft | 12 ft | – | – | 17 ft | 20 ft |

| 4″ | 7 ft | 12 ft | – | 14 ft | 17 ft | 20 ft |

| 5″ | 7 ft | – | 13 ft | 14 ft | 17 ft | 20 ft |

| 6″ | 8 ft | – | 13 ft | 14 ft | 17 ft | 20 ft |

*Champion Fiberglass UL Listed Support Spans

The true savings come not only from materials cost as fewer hangers and less strut are required, but from the savings on installation and labor hours. GRC/RMC is the heaviest-weight and thickest-wall steel conduit, and corrosion resistance is achieved via a zinc coating. This coating may be applied on both the conduit’s interior and exterior, or on the interior only.

GRC couplings are mechanical, with threads on each end, contributing to substantial installation time requirements.

How Does Champion Fiberglass Conduit Support Spacing Compare to PVC-coated Steel?

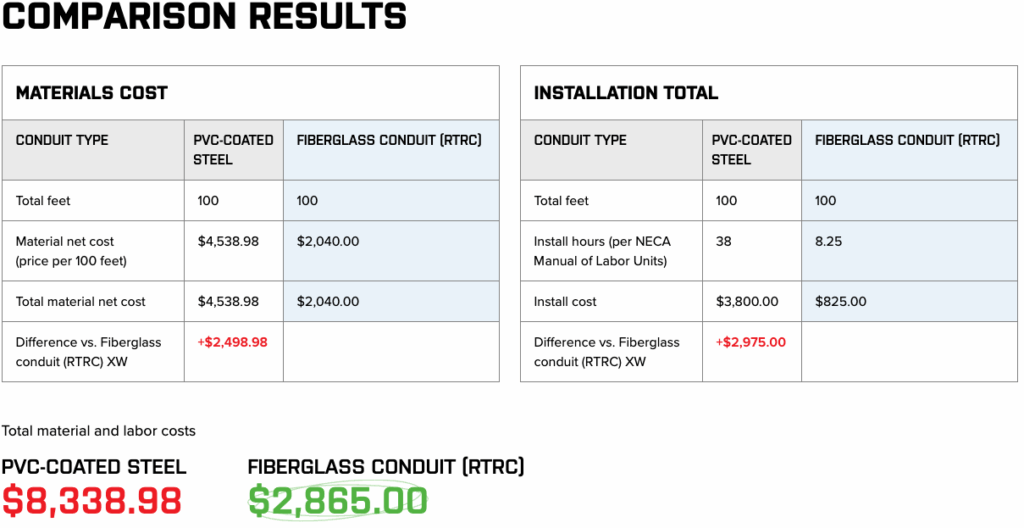

PVC-coated steel is similar to GRC conduit in both weight and poor field handling. Per 100 feet of 4” conduit, Champion Fiberglass XW Type conduit represents over $5,000 in project savings when compared to PVC-coated steel conduit.

While the same number of hangers are required (5), the time to install Champion Fiberglass is only 8.25 labor hours, compared to 38 labor hours required to install the same length of PVC-coated steel.

Champion Fiberglass materials are also less expensive, further contributing to cost savings. For the same number of conduit supports on a project, PVC-coated steel adds $2,498.98 to materials cost and $2,975 to installation costs.

Benefits of Champion Fiberglass Conduit:

- Excellent field handling.

- UV-stable and on-toxic, releasing zero halogens when burned.

- High flexural strength, fiberglass retains its original shape after impact or compression.

- Inherently corrosion resistant, featuring the broadest range of corrosion resistance of all in-market conduit materials.

See How Conduit Support Spacing Requirements Can Impact Projects

Champion Fiberglass makes it easy to compare costs of materials and installation for multiple conduit materials including fiberglass (RTRC), PVC-coated steel, GRC, aluminum, and stainless steel, specific to projects based on hourly rates, conduit diameter and length with our conduit calculator.

To learn more about conduit support spacing requirements across substrates and which conduit will be best suited for projects to ensure maximum cost savings without sacrificing strength, contact a local electrical conduit Rep.