An Innovative Data Center Build-out

Our client, a tech company known for leading-edge solutions, was building a new data center. Although Galvanized Rigid Steel elbows have historically been the go-to for data center conduit stub-ups, they were looking for ways to save money on their initial build-out, and hopefully, to find a solution that would deliver long-run savings, as well.

CHALLENGE

It makes sense that data centers would adopt innovative, high-tech building materials – materials adaptable enough to support the goals they’re working toward today and strong enough to stand up to tomorrow’s challenges, as well.

The first challenge in data center construction, as in any project, is to control costs. As mentioned, Galvanized Rigid Steel elbows have historically been used in data center build-outs. However, the relatively high weight of GRC contributes to increased starting costs.

The next challenges to data center integrity are the susceptability to underground faults and the burn through that is characteristic of PVC conduit. In creating a stable system of optical fiber raceways, engineers need materials that feature fault resistance and a low coefficient of friction; materials that minimize burn through when pulling cable.

Add in the possibility of corrosion created by atmospheric contamination and the risk of losing valuable infrastructure and information to a fire, and data centers have a long list of challenges.

Luckily, the list of products that address each and every one of these challenges is a very short one.

SOLUTION

The product that hit every “must-have” on that challenge list was Champion Fiberglass Reinforced Thermosetting Resin Conduit (RTRC) elbows. Our client realized there was an opportunity to save on material, freight and manpower costs up front – without sacrificing strength or safety – by replacing GRC elbows with Champion Fiberglass reinforced elbows.

As data center design focuses more and more on density – i.e. fitting as much server space as possible into the available square footage – elbows must support the amount of cable necessary while minimizing burn through. Champion Fiberglass elbows feature a low coefficient of friction and a single-circuit winding process, contributing to low burn through, fault resistance and longer life for vital cables.

Finally, there’s the challenge of corrosion. Although many wouldn’t consider data centers to be corrosive environments, according to major IT equipment manufacturers, the number of data centers with contamination-related failures is on the rise. Particulate and dust contamination contribute to data center breakdowns, and Champion Fiberglass elbows are built to withstand corrosion associated with foreign matter. And in the case of a data center fire, fiberglass conduit emits very low smoke and zero halogens – not the chlorine or bromine released by PVC-based materials.

Choosing Champion Fiberglass elbows showed immediate savings in terms of easier field handling, lower freight cost and a lower total installation cost. And thanks to the product’s corrosion resistance, fault resistance and elimination of cable burn through, these elbows will be supporting our client’s innovations for the entire lifecycle of the facility.

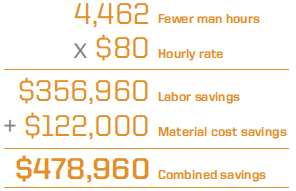

RESULTS

By replacing galvanized rigid steel elbows with Champion Fiberglass elbows, our data center client was able to build real savings. That’s some fiberglass conduit data you can take to the bank.

Fiberglass conduit emits very low smoke and zero halogens – not the chlorine or bromine released by PVC- based materials.