By Scott Patchan

- Conduit installation cost is driven more by labor, supports, and handling than material price alone

- Learn how lightweight, nonmetallic conduit can reduce labor hours in industrial and utility installations

- Understand how durability and extended support spans contribute to lower total cost of ownership

Electrical conduit selection has a direct and measurable impact on conduit installation cost, particularly in large-scale industrial and utility projects where labor, access constraints, and long service life requirements dominate budget planning.

While material price is often the first comparison point, experienced engineers and contractors know that installed cost and total cost of ownership determine real project value. Champion Fiberglass® conduit systems are engineered to reduce conduit installation cost from the start, with faster installation and continued reliability through decades of service in demanding environments.

Installed Cost Starts with Labor Efficiency

Electrical labor remains one of the largest variables in project budgets. In industrial plants, substations, and utility infrastructure, heavy conduit systems require more manpower, mechanical handling, and installation time. In elevated, congested, or remote environments, those costs compound across hundreds or thousands of feet.

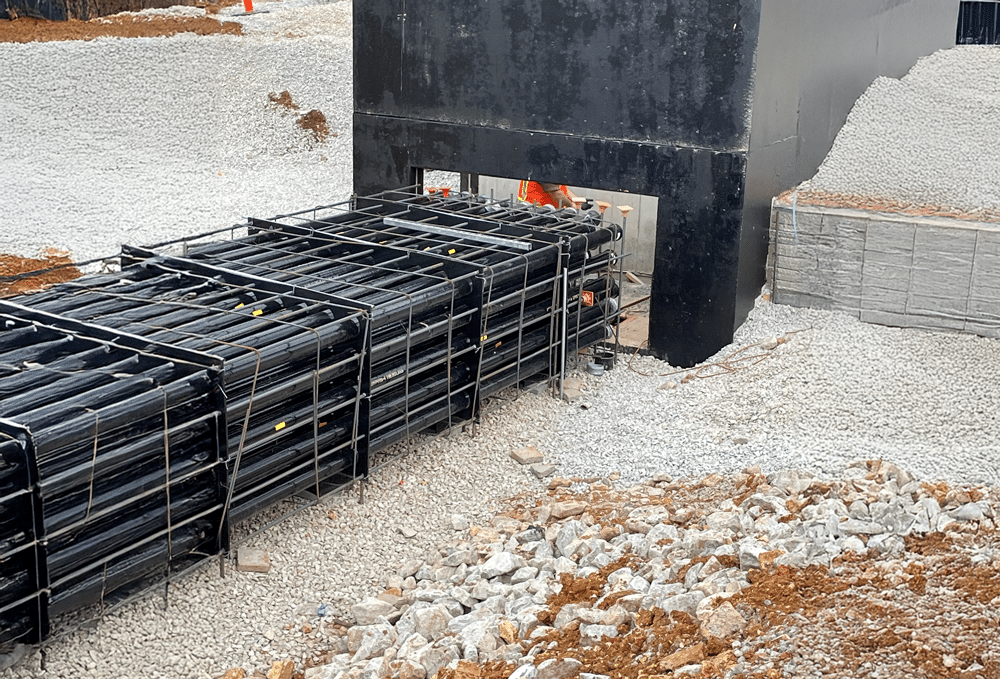

Fiberglass conduit reduces labor exposure through lightweight construction and straightforward handling, an advantage that becomes particularly clear in large-scale utility and industrial installations. Crews can move, position, and secure long conduit runs with fewer installers and less equipment, even in elevated, remote, or congested environments such as pipe racks, under-bridge crossings, and extended right-of-way corridors.

Across utility projects, Champion Fiberglass conduit has been frequently used in applications such as charging stations, pole risers, underground duct banks, and wind and solar installations. In these environments, long, repetitive conduit installations amplify labor savings, while in bridge projects, extended support spans reduce hanger counts and installation time over hundreds or thousands of feet.

In industrial facilities and processing plants, including wastewater treatment facilities and chemical processing sites, fiberglass conduit supports faster installation while standing up to corrosive conditions. Lightweight handling helps crews work efficiently in active facilities and elevated racks, while corrosion resistance reduces downtime associated with maintenance or future replacement.

Fewer Supports Reduce Installation Time and Cost

Champion Fiberglass conduit is UL listed for extended support spans. Longer allowable spacing between supports reduces the total number of hangers required along a run.

This advantage delivers multiple cost-saving benefits:

- Reduced material quantities for supports

- Less drilling and fastening

- Faster installation progress

- Lower exposure to jobsite safety risks

On large-scale infrastructure, utility, industrial, or transportation projects, extended support spans can eliminate many individual support points, significantly reducing labor and coordination effort.

Faster Handling Improves Jobsite Productivity

According to the NECA Manual of Labor Units, Champion Fiberglass conduit requires less man/hours to install vs traditional material type (SCH40 & 80 PVC, GRC & PVC coated steel) conduits. Lightweight fiberglass conduit improves productivity beyond installation alone. Fiberglass conduit is easier to stage, transport, and position, particularly in elevated, confined, or under-bridge applications where access is limited.

Durability That Protects Long-Term Value

Reducing conduit installation cost should not compromise long-term performance. Fiberglass conduit delivers long-term value through corrosion resistance, mechanical strength, and resistance to moisture, chemicals, and UV exposure.

Unlike metallic systems, fiberglass conduit does not rust or require coatings to maintain integrity in corrosive environments. This durability minimizes maintenance costs and reduces the likelihood of premature replacement, an important consideration for utilities, transportation agencies, and industrial facilities with long service-life expectations.

For engineers and project managers, this durability:

- Helps reduce maintenance

- Minimizes replacement risk

- Supports long service life expectations

Total Cost of Ownership Drives Better Decisions

When evaluating conduit systems, the lowest material price rarely equates to the lowest total project cost. Installed labor, schedule reliability, safety considerations, and lifecycle performance must all be considered together.

Champion Fiberglass conduit systems are designed to reduce the total cost of ownership by:

- Lowering installation labor hours

- Reducing support hardware and accessories

- Improving jobsite efficiency

- Delivering long-term durability in harsh environments

- Improved safety during installation due to the lightweight nature of the conduit

These advantages allow projects to stay on schedule, control labor exposure, and reduce long-term risk.

Built for Demanding Applications. Made in America.

Champion Fiberglass conduit is manufactured in Spring, Texas and engineered to meet the demands of utilities, transportation infrastructure, industrial facilities, and commercial projects nationwide. Backed by decades of application experience, Champion Fiberglass products are designed to support project success from planning through installation and beyond.

A leading manufacturer in the electrical business, Champion Fiberglass is the only conduit-industry business to have received ISO 9001, 14001, and 45001 certifications.

Download the Electrical Conduit Cost Savings Guide

The Champion Fiberglass Electrical Conduit Cost Savings Guide breaks down how fiberglass conduit helps reduce installation labor, improve jobsite efficiency, and lower the total cost of ownership across real-world applications.

Download the guide to learn how:

- Installation labor impacts total conduit cost

- Extended support spans reduce material and labor requirements

- Lightweight conduit improves productivity in industrial and utility environments

This article was originally published on May 29, 2020, and recently updated with new and helpful information.