Application Overview

Despite a 10% spending decline in 2020, the data center market is expected to rebound globally over the next few years. The Internet of Things, 5G networks, and hyperscale data centers are fueling the growth. In the US, the data center construction market is expected to reach $121.56 billion by 2027, according to Grand View Research.

Protection of the cables and assets specific to data centers requires a durable, corrosion-resistant conduit system. Our cost-effective, American-made RTRC electrical conduit can be found in the data centers of the largest tech companies and telecommunications providers including software and search giants and microchip manufacturers.

Featured Video

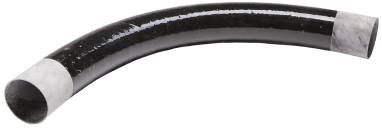

Champion Fiberglass’s lightweight, corrosion-resistant, “no burn through” elbows are the right choice for leading-edge data center engineering. They enable design flexibility without sacrificing strength, they fight corrosion, and their lightweight nature contributes to increased installation savings.

Elbow Calculator

Have a Data Center project in the works? Compare the material and installation costs of Champion Fiberglass elbows to other elbow material types by using the new Champion Elbow Calculator tool.

Why Use Fiberglass Conduit for Data Center Projects?

Characteristics like lack of burn-through, low coefficient of friction, and cable fault resistance make fiberglass conduit elbows an ideal solution to protect data center infrastructure.

Traditional materials including galvanized rigid steel, aluminum and PVC-coated steel conduit will weld wire to the inside of the conduit during fault conditions, while fiberglass conduit is not affected.

Fiberglass RTRC conduit is lightweight, making it easier to handle and transport and less labor intensive to install than traditional alternatives per the NECA Manual of Labor Rates.

Fiberglass conduit offers one of the lowest coefficients of friction available for conduit systems and is completely resistant to any of the current pulling lubricants’ corrosive properties. Keeping conduit intact means you don’t have to worry about damaged conduit and resulting repairs.

Innovative Solutions to Protect Data

It’s clear why some of the largest tech and telecommunications companies trust Champion Fiberglass® to safeguard data center infrastructure with RTRC conduit. In a recent data center build-out replacing galvanized rigid steel elbows with Champion Fiberglass elbows contributed to more than $400,000 in combined project savings.

Champion Fiberglass’s lightweight “no burn-through” fiberglass conduit elbows enable design flexibility without sacrificing strength and their lightweight nature contributes to increased installation savings.

Featured Product

Champion

Fiberglass Elbows

Delivering labor-saving, no-burn-through fiberglass elbows, fast.